Customer Leading cosmetics brand

Contractor ASCOAT Contracting

Sector Manufacturing

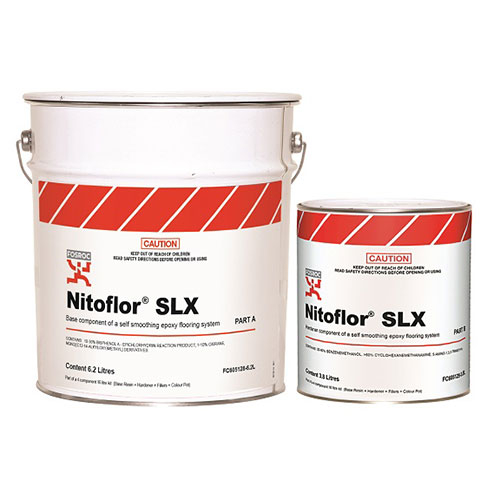

Products

- Nitoflor SLX

A leading Melbourne-based cosmetics brand had outgrown its location and needed a new production facility. Fosroc Nitoflor SLX was used to create a seamless flooring solution that would to meet the 'pharmaceutical grade' hygiene requirements.

Cosmetic production plant gets the perfect base with Nitoflor SLX

With a 20-year heritage manufacturing skincare, perfume and home fragrances from its Melbourne headquarters, a leading cosmetics brand had outgrown its location and needed a new production facility.

Nitoflor SLX was the ideal flooring solution for a client seeking 'pharmaceutical grade' hygiene. “The floors had to be perfect, with a seamless transition between the floor and the walls,” says Fosroc ANZ's industrial flooring specialist, Greg Smith.

A proven applicator chooses the right product

The construction project manager reached out to ASCOAT Contracting, which has experience in the pharmaceutical sector. ASCOAT's specialist applicators recommended Nitoflor SLX.

This self-smoothing, solvent free epoxy screed creates a dense, hygienic finish. It is easily cleaned and offers good resistance to wear and tear from a wide range of chemicals. A special hardener component provides extra protection from water staining.

Easy application and fast curing

Supplied as a pre-measured, multicomponent system ready for on-site mixing, the product was applied at a thickness of 2 to 3 mm. The ASCOAT team followed an efficient four-step process of pouring, gauge raking, spreading/smoothing and spike rolling the product.

"Some of these self levelling epoxies can be difficult to lay," Greg explains. "SLX produces a very, very good finish and consistency that is repeatable. There were zero issues during the application across 5,000 square metres!"

For clients who need to minimise downtime, the flooring can be walked on after 24 hours.