Fosroc Nitoproof 210 is a fast and cost-effective waterproofing solution that also protects concrete from invasive plant roots.

With root inhibiting additives built in, it is ideal for waterproofing the following surfaces:

- retaining walls

- planter boxes

- below ground water tanks

- foundation walls.

This self priming, water based product dries into a bituminous rubberised membrane. Its smooth, non-sag formulation enables vertical and horizontal application.

Why choose Fosroc Nitoproof 210?

Suitable for residential and commercial construction, Nitoproof 210 forms a highly flexible and seamless waterproofing membrane. Here are the top reasons why specifiers and applicators choose this liquid applied product:

- self priming on most common substrates

- excellent cold flexibility and elongation

- root penetration inhibitor

- low VOC

- fast drying

- excellent resistance to ponding water

- non-toxic

- non-flammable.

Protecting the foundations at Coombabah State High School

Constructed on a sloping site, the new learning centre at Coombabah State High School includes a ground floor built into the landscape. Nitoproof 210 was selected to waterproof the foundation walls before the surrounding area was back-filled. This level has since been topped with a suspended deck, which will become the main outdoor entry to the building.

Fosroc's Specification Manager in Queensland, Shawn Perry specified Nitoproof 210 for the task. Account manager Eric Repetto worked with the application team at Proseal during the application.

"It is a versatile product that is easy to use across all applications. It's fast to apply and dry," says Eric. "In most Australian climates, you can complete the application in one or two days and backfill the area three days later."

The concrete blocks were coated with Nitoproof 210. Sheet drain and protection board were both used to protect the membrane during back-filling.

Application steps

After priming, two coats of Nitoproof 210 are applied by brush, roller or a standard airless sprayer.

"We recommend two coats of 750 microns each. This will give you a 1.5mm wet film thickness, resulting in a final membrane of 1.0 to 1.3mm," Eric explains.

Prime: Nitoproof 210 is self-priming on most porous surfaces. Applicators simply dilute the product with a 1:1 ratio of water before applying by brush or roller. "The primer dries very quickly. By the time you get to the end of a wall, it will be ready for the first coat," says Eric.

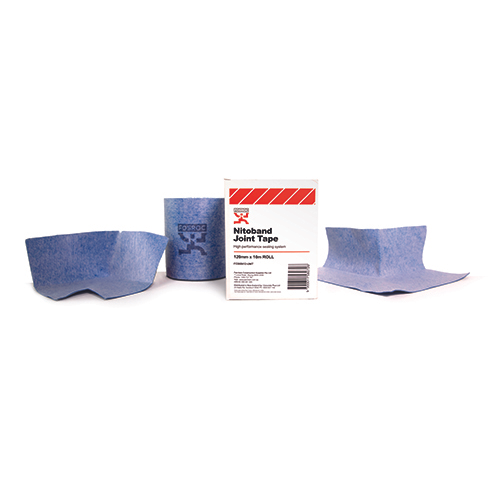

Joints: The Nitoband System can be applied to any substrate joints at this stage.

First coat: Apply the first coat in one direction. Allow four hours for the film to dry. Shorter times may be acceptable in good drying conditions.

Second coat: Apply the next coat perpendicular to the previous coat. Again, apply in a single direction to create a series of 90 degree angles with the previous coat.

Inspect: Check there are no pinholes in the membrane. A further coat may be required to resolve any imperfections.

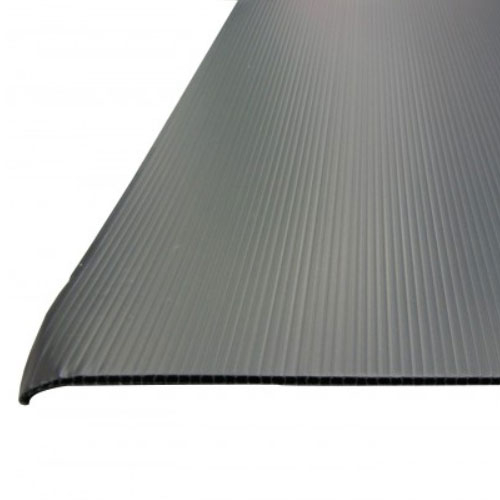

Protect: If the membrane is to be backfilled, avoid any mechanical damage with a layer of Proofex Protection Board PP and/or Proofex Sheetdrain 81.

Back-fill: Depending on your climate, wait three to four days after application before back-filling.

Find out more

- Download the Fosroc Waterproofing Liquid Applied Brochure

- Explore waterproofing options via our Product Selector

- Complete the 'Get in touch' form at the bottom of this page. We will be in touch to help you find the right product.