New Fosroc Proofex ORG and Proofex OFB are advanced Thermoplastic Polyolefin (TPO) waterproofing membranes designed for superior performance in various construction applications.

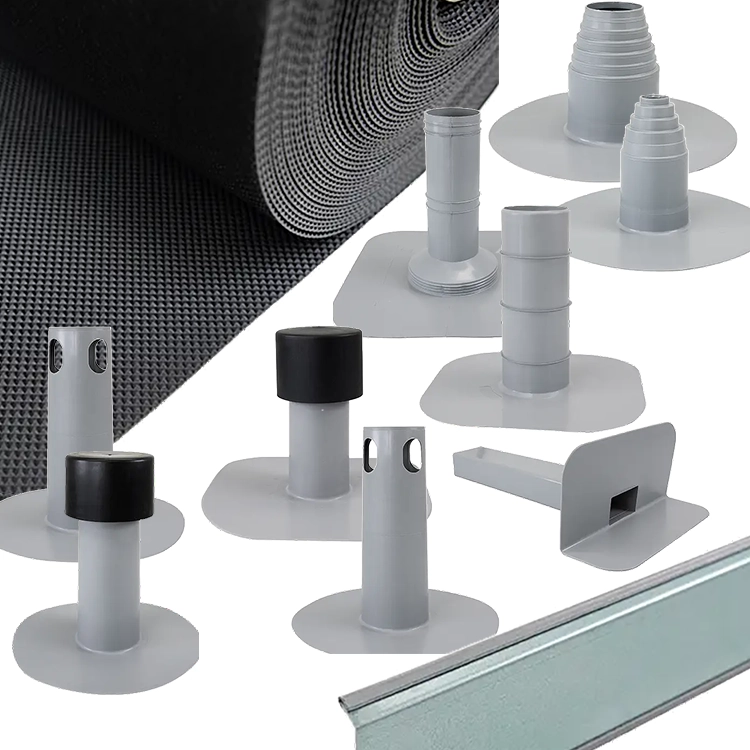

Proofex ORG is a reinforced sheet membrane that is mechanically fixed, while Proofex OFB is a fleece-backed membrane that provides a fully bonded system for superior adhesion to substrates.

Both products offer outstanding weather resistance, UV stability, and long service life, making them an ideal choice for a wide range of waterproofing applications, in particular roofing applications.

What are TPO membranes?

TPO membranes are single-ply, flexible polyolefin sheets that provide excellent waterproofing and durability. Made from polypropylene copolymers, they contain no plasticisers, making them environmentally friendly and resistant to degradation. They offer flexibility, impact resistance, and superior welding capabilities.

About Fosroc's Proofex TPO product range

Fosroc's range includes TPO membranes for both above and below-ground waterproofing. Proofex ORG and Proofex OFB are at the forefront of this range, providing industry-leading solutions for roof waterproofing. These membranes are AS4654.1 compliant, root-resistant, recyclable, and compatible with various insulation and bitumen roofing systems.

Where can Proofex TPO membrane systems be used?

Proofex ORG and Proofex OFB are versatile and can be applied in multiple environments, including:

- Flat and sloping roofs

- Pitched and curved roofs

- Foot-trafficable roof areas (Maintenance Traffic)

Their high elongation and durability make them suitable for a broad range of construction types, from commercial buildings to residential properties and infrastructure projects.

Why choose Proofex ORG and OFB?

- Superior weather and UV resistance: Both membranes are designed to withstand extreme weather conditions and prolonged UV exposure, ensuring longevity.

- Fast and easy installation: Welded joints provide maximum watertightness, reducing installation time and improving efficiency.

- Environmentally friendly: Free from volatile organic compounds (VOCs) and plasticisers, these membranes contribute to sustainable construction.

- Exceptional strength and flexibility: With elongation rates of up to 950% for Proofex ORG and 700% for Proofex OFB, these membranes accommodate structural movements without compromising performance.

TPO versus PVC. What are the key differences?

There are a number of benefits to TPO membranes when compared with traditional PVC:

- Weight: TPO is approximately 25% lighter than PVC.

- Composition: PVC contains plasticisers, which can leach into the environment, while TPO is made from stable polypropylene copolymers.

- Safety: Unlike PVC, TPO does not emit toxic fumes during welding, making installation safer.

- Welding efficiency: TPO welds at a lower temperature (300-350°C) compared to PVC (500-550°C), allowing for a more energy-efficient installation process.

- Durability: TPO has greater tear and impact resistance, as well as higher elongation properties (close to 1000% for TPO vs. 300% for PVC).

- Longevity: TPO membranes offer a typical design life of 40 years.

Environmental benefits of Proofex ORG and OFB

Fosroc Proofex ORG and Proofex OFB contribute to sustainable construction by being:

- Fully recyclable

- Non-toxic with no VOCs

- Compatible with EPS insulation without a separation geotextile

- Energy-efficient in manufacturing and installation

Their low environmental impact makes them a preferred choice for eco-conscious roofing projects.

Find out more

- Visit the Proofex OFB product page

- Visit the Proofex ORG product page

- Contact the Fosroc Specification Team

Get in touch

Contact Fosroc today to learn more about how Fosroc Proofex ORG and OFB can enhance your next project. Scroll to the bottom of this page to send us a waterproofing enquiry. Our expert team will be in touch to assist.